infrastructure

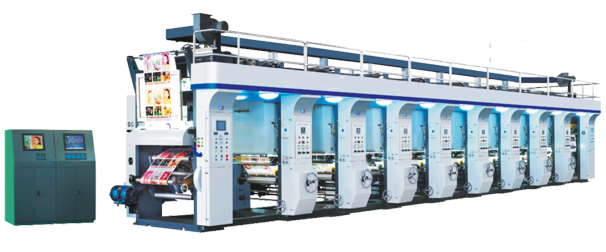

Automatic 8-Colour Rotogravure Printing

Our Rotogravure printing is a high-speed, high-quality printing process that uses engraved cylinders to transfer ink onto a substrate. A rotogravure printing machine is a specialized printing press that is designed to produce high-quality prints using this process. Here are some key features of a rotogravure printing machine:

Engraved cylinders: Rotogravure printing machines use engraved cylinders to transfer ink onto the substrate. The cylinders are typically made of steel and are etched with tiny cells that hold the ink. As the cylinder rotates, the ink is transferred from the cells to the substrate.

Substrate handling: Rotogravure printing machines can handle a wide range of substrates, including paper, plastic, and metal. The machines are designed to feed the substrate through the press at a consistent speed to ensure accurate printing.

Ink delivery system: Rotogravure printing machines use a sophisticated ink delivery system that ensures consistent ink coverage and color accuracy. The ink is typically delivered to the engraved cylinder through a series of rollers and doctor blades.

Drying system: After the ink is transferred to the substrate, it needs to be dried to ensure that it adheres properly. Rotogravure printing machines use a variety of drying systems, including hot air, infrared, and ultraviolet.

Automation and control: Rotogravure printing machines are highly automated and can be controlled using sophisticated software. This allows for precise control over the printing process, including ink density, color accuracy, and registration.

Our 8-color Rotogravure printing machines are widely used in the packaging, label, and pharmaceuticals foil & Blister foil, where high-quality printing is essential. It offers superior print quality and is ideal for our high-volume printing runs.

Lamination Machine

Our chemical-based lamination refers to the process of bonding two or more layers of material together using a chemical adhesive. The adhesive is typically applied to one or both of the layers of material before they are pressed together and heated to create a strong bond.

There are various types of chemical adhesives that can be used for lamination, including solvent-based, water-based, and hot melt adhesives. The type of adhesive used will depend on the materials being laminated and the desired outcome.

Solvent-based adhesives are typically used for laminating materials such as plastics, metals, etc. They use a solvent to dissolve the adhesive and create a strong bond between the layers of the material.

Water-based adhesives are often used for laminating paper products. They use water as the primary solvent and are considered to be more environmentally friendly than solvent-based adhesives.

Chemical-based lamination is commonly used in various industries, including printing, packaging, and manufacturing. It is used to create a wide range of products such as laminated labels, and packaging materials.

Automatic Slitting Systems

We are dedicated to providing high-quality and innovative products that meet the diverse needs of our customers. One of our flagship offerings is the Automatic Slitting Machines, which is designed to streamline and optimize the slitting process for a wide range of materials.

Our Automatic Slitting Machines are powerful and versatile tools that can handle a variety of substrates, including films, papers, foils, and laminates. It is ideal for converting large rolls of material into smaller widths, making it an essential tool for any converter looking to increase efficiency and reduce waste.

One of the key features of our Automatic Slitting Machine is its user-friendly interface. The machine is easy to operate and can be configured to meet the specific needs of each customer. It comes equipped with a range of advanced features, such as automatic tension control, web guiding, and automatic blade

positioning, which helps to ensure accurate and consistent slitting results.

In addition to its advanced features, our Automatic Slitting Machines are built to last. These are constructed with high-quality materials and components and are rigorously tested to ensure reliable performance over time. It also features a modular design, which allows for easy maintenance and repairs and can be customized to meet the specific needs of each customer.

At our company, we understand that each customer has unique needs and requirements. That’s why we offer a range of customizable options for our Automatic Slitting Machines, including different slitting widths, blade configurations, and control systems. Our team of experts is always available to provide guidance and support, and we are committed to working closely with each customer to ensure their complete satisfaction.

Whether you are looking to increase efficiency, reduce waste, or improve the quality of your finished products, our Automatic Slitting Machines are the perfect solution. With its advanced features, user-friendly interface, and customizable options, it is the ultimate tool for any converter looking to stay ahead of the competition. Contact us today to learn more about how our Automatic Slitting Machines can help take your business to the next level.